A carrying solution designed to safeguard contents from moisture while offering the distinctive aesthetic associated with a particular brand is under consideration. This item combines functionality, protecting belongings from light rain or spills, with a recognizable design known for its patterns and construction. Examples include models suitable for students requiring protection for books and electronics, or travelers seeking a lightweight, weather-resistant option for personal items.

The significance of such a product lies in its dual purpose: providing peace of mind regarding the safety of carried items and expressing individual style preferences. Historically, weatherproof bags were often purely utilitarian. This example blends practicality with fashion, appealing to a demographic that values both aspects. The benefits extend to the longevity of transported goods, reducing potential damage from environmental factors, and potentially decreasing the frequency of replacement purchases.

The following sections will delve into specific aspects of this type of product, including materials used, construction techniques contributing to water resistance, available features, and considerations for selecting the most appropriate model based on individual needs.

Practical Usage Considerations

Maximizing the lifespan and effectiveness of a water-resistant backpack requires adherence to certain guidelines. These suggestions promote both its functionality and aesthetic appeal.

Tip 1: Inspect Seams Regularly: Diligently examine the seams and stitching for any signs of wear or separation. Compromised seams can reduce the bag’s water resistance and structural integrity. Early detection allows for timely repairs.

Tip 2: Utilize Appropriate Cleaning Methods: Adhere to the manufacturer’s recommended cleaning instructions. Harsh detergents or abrasive cleaners can damage the water-resistant coating or the fabric itself. Gentle hand washing with mild soap is generally advised.

Tip 3: Avoid Overloading: Exceeding the recommended weight capacity can strain the seams and zippers, potentially compromising water resistance and leading to premature wear. Distribute weight evenly to minimize stress points.

Tip 4: Secure Zippers and Closures Fully: Ensure all zippers and closures are completely sealed to prevent water ingress. Inspect zippers for smooth operation; lubrication may be necessary if resistance is encountered.

Tip 5: Store Appropriately: When not in use, store the backpack in a dry, well-ventilated area. Avoid prolonged exposure to direct sunlight or extreme temperatures, as this can degrade the fabric and water-resistant coating.

Tip 6: Consider Water-Resistant Sprays: Re-apply a suitable water-resistant spray periodically, especially after washing or prolonged use. This helps to maintain the fabric’s water-repellent properties.

Adherence to these recommendations will contribute to the sustained performance and longevity of the water-resistant backpack, ensuring it remains a reliable and aesthetically pleasing accessory.

The concluding section will summarize the key aspects discussed and offer final insights on the selection and maintenance of such items.

1. Fabric Durability

The relationship between fabric durability and the overall performance of a water-resistant backpack is fundamental. Fabric choice directly influences the backpack’s resistance to wear and tear, its ability to repel water, and its longevity. A robust fabric, such as ripstop nylon or polyester with a high denier rating, withstands abrasions and punctures more effectively than a thinner, less durable material. This, in turn, reduces the likelihood of damage that could compromise the water-resistant coating or allow water to penetrate the interior. For example, a backpack constructed from a low-denier fabric might quickly develop tears along seams or at stress points, rendering the water-resistant treatment ineffective during even light rainfall.

The practical significance of fabric durability extends beyond simple resistance to physical damage. A more durable fabric maintains its structural integrity over time, preventing stretching or sagging that can alter the backpack’s shape and reduce its carrying comfort. Furthermore, durable fabrics often possess inherently better water-repellent properties, enhancing the effectiveness of any applied water-resistant coating. Consider two backpacks subjected to identical conditions: the one utilizing a higher-quality, durable fabric will likely maintain its water resistance for a longer period, requiring less frequent re-treatment with water-repellent sprays. This has a direct impact on the backpack’s long-term cost of ownership and user satisfaction.

In summary, fabric durability is a critical determinant of a water-resistant backpack’s performance, longevity, and overall value. Selecting a backpack constructed from a robust, high-quality fabric is essential for ensuring its ability to withstand the rigors of daily use and maintain its water resistance over time. While other factors, such as seam construction and zipper quality, also contribute to the backpack’s performance, fabric durability serves as the foundation upon which these other features build.

2. Seam Construction

Seam construction constitutes a critical element in determining the overall water resistance of a backpack, particularly in models designed to safeguard contents from moisture intrusion. The manner in which fabric panels are joined directly impacts the ability of the backpack to prevent water penetration, especially during exposure to rain or spills. Inferior seam construction, characterized by loosely sewn or exposed seams, provides direct pathways for water to enter the interior compartment. Conversely, meticulously constructed seams, employing techniques such as taping, welding, or folding, significantly enhance water resistance by creating a barrier against moisture ingress. Therefore, seam construction is not merely an aesthetic detail but a functional imperative in a water-resistant backpack.

Techniques employed in seam construction vary, each offering different levels of water resistance. Taped seams, for instance, involve applying a waterproof tape over the stitched seam, effectively sealing the needle holes and preventing water from seeping through. Welded seams, on the other hand, utilize heat and pressure to fuse fabric panels together, creating a seamless and watertight bond. Folded seams, often found in higher-quality backpacks, involve folding the fabric edges over each other before stitching, providing an extra layer of protection against water penetration. The choice of seam construction technique depends on factors such as the fabric type, the intended use of the backpack, and the desired level of water resistance. Backpacks designed for heavy-duty outdoor use often feature a combination of these techniques to maximize protection.

In summary, seam construction plays a pivotal role in the water resistance and overall performance of a backpack. Selecting a backpack with well-constructed seams, employing techniques such as taping, welding, or folding, is essential for ensuring the protection of carried items from moisture. While other features, such as fabric durability and zipper quality, also contribute to water resistance, seam construction remains a critical factor to consider when evaluating the suitability of a backpack for use in wet or unpredictable conditions. The effectiveness of seam construction directly influences the long-term durability and reliability of the product.

3. Zipper Quality

The functionality and water resistance of a backpack are intrinsically linked to zipper quality. Zippers serve as crucial closure mechanisms, and their integrity is paramount in preventing water ingress. Substandard zippers, characterized by weak construction, inadequate sealing, or susceptibility to corrosion, compromise the protective capabilities of the product. Inadequate closure allows water to penetrate the interior, negating the benefits of water-resistant fabrics and seam construction. A real-world example involves a student whose electronics were damaged due to a faulty zipper allowing rainwater to seep into the backpack during a commute. The practical significance underscores the importance of evaluating zipper quality when selecting a product.

High-quality zippers, conversely, contribute significantly to a backpack’s ability to withstand exposure to moisture. Features such as water-resistant coatings, tightly interlocking teeth, and robust construction materials enhance their protective function. Moreover, durable zippers resist wear and tear, ensuring reliable closure over extended periods of use. For instance, backpacks equipped with waterproof zippers and reinforced stitching around the zipper area provide a superior level of protection compared to those with standard zippers. The implementation of flaps or storm guards over the zipper further reduces the likelihood of water penetration, adding another layer of defense against environmental elements.

In summary, zipper quality is an indispensable component of a water-resistant backpack. The selection of a product with durable, water-resistant zippers is essential for safeguarding contents from moisture damage. While challenges may arise in assessing zipper quality prior to purchase, examining material specifications, closure mechanisms, and user reviews provides valuable insights. The relationship between zipper quality and water resistance highlights the need for careful consideration during the purchase process, ensuring long-term performance and protection for carried items.

4. Coating Effectiveness

The capacity of a water-resistant backpack to protect its contents from moisture hinges significantly on the effectiveness of its water-repellent coating. This coating acts as the primary barrier against water penetration, dictating the backpack’s performance in various environmental conditions.

- Type of Coating

The selection of coating material directly impacts water resistance. Durable Water Repellent (DWR) coatings are commonly used. The effectiveness of DWR diminishes over time with abrasion and washing. Polyurethane (PU) coatings offer higher water resistance but may be less breathable. The choice between these, and other coating types, represents a trade-off between water protection, durability, and cost. For example, a backpack intended for light use may utilize a basic DWR coating, while a backpack designed for harsher environments would necessitate a more robust PU or silicone-based coating.

- Application Method

The method by which the coating is applied to the fabric influences its longevity and uniformity. Spray-on coatings may be less consistent than coatings applied through immersion or lamination processes. Uneven coating application can lead to weak spots where water can penetrate. For instance, a backpack with a poorly applied coating may exhibit localized areas of water leakage during rainfall, despite the overall fabric possessing water-resistant properties.

- Maintenance and Reapplication

The longevity of a water-resistant coating is not indefinite. Exposure to sunlight, abrasion, and detergents degrades the coating’s effectiveness over time. Regular cleaning and reapplication of a water-repellent treatment are necessary to maintain the backpack’s protective capabilities. Failure to properly maintain the coating will result in a gradual reduction in water resistance, ultimately compromising the backpack’s functionality. An example is the need to reapply DWR to a backpack after washing to restore its water-repellent properties.

- Testing and Standards

Standards dictate water resistance levels in materials. Hydrostatic head tests measure the amount of water pressure the fabric can withstand before leakage. Understanding these ratings allows assessment and comparison of coatings. Higher ratings provide superior protection, but increased cost can impact product decisions. Using testing and standards gives reliable measurements to assess product coatings objectively.

Therefore, understanding these factors regarding coating effectiveness is critical in determining its utility and longevity. Proper attention to coating type, application, maintenance, and testing directly influences the backpack’s ability to protect its contents from water damage, ensuring a reliable and durable product.

5. Design Aesthetics

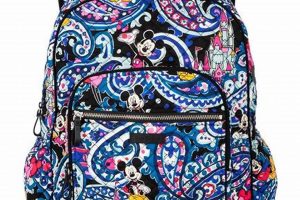

Design aesthetics, in the context of a “vera bradley water resistant backpack,” transcend mere visual appeal; they are integral to the product’s market positioning and consumer perception. The brand’s signature patterns and color palettes directly influence purchasing decisions, often serving as the primary differentiator in a competitive market segment. The cause-and-effect relationship is clear: distinctive designs generate brand recognition and foster customer loyalty. The importance of design aesthetics lies in their ability to transform a utilitarian item into a fashion statement, thereby increasing its desirability and perceived value. For example, the use of vibrant floral prints or quilted textures immediately identifies the backpack as belonging to a specific brand, influencing consumer choice.

The practical significance of understanding design aesthetics extends to the product development process. The selection of patterns, colors, and materials must align with the brand’s established identity and target demographic preferences. A departure from these established norms risks alienating existing customers and weakening brand recognition. Furthermore, the integration of aesthetic elements should not compromise the backpack’s functionality or water resistance. For instance, the application of intricate embroidery could potentially weaken the fabric’s water-repellent properties, requiring careful consideration of materials and construction techniques. The aesthetic choices should also consider ergonomic factors, such as the placement of pockets and straps, to ensure comfort and ease of use.

In summary, design aesthetics are a critical component of a “vera bradley water resistant backpack,” influencing its market appeal and consumer perception. Successful integration of aesthetic elements requires a delicate balance between visual appeal, brand identity, functionality, and water resistance. The challenges lie in maintaining brand consistency while adapting to evolving consumer preferences and technological advancements in materials and manufacturing processes. Recognizing and addressing these challenges is essential for sustaining long-term product success and brand loyalty.

Frequently Asked Questions

The following section addresses common inquiries regarding the functionality, care, and selection of these items. The information aims to provide clarity and facilitate informed purchasing decisions.

Question 1: How effective is the water resistance of this type of backpack in heavy rain?

The degree of water resistance varies based on the specific materials and construction techniques employed. While designed to withstand light rain and splashes, prolonged exposure to heavy rainfall may compromise the backpack’s ability to keep contents completely dry. It is recommended to seek additional protection for sensitive items during severe weather conditions.

Question 2: What is the proper method for cleaning a water resistant backpack without damaging the coating?

Manufacturer instructions should always be consulted first. Generally, spot cleaning with a mild detergent and a soft cloth is recommended. Avoid harsh chemicals, abrasive cleaners, and machine washing, as these can degrade the water-resistant coating and damage the fabric.

Question 3: Can the water-resistant coating be reapplied, and if so, how often?

Yes, commercially available water-repellent sprays designed for fabrics can be used to restore the coating’s effectiveness. The frequency of reapplication depends on the backpack’s usage and exposure to the elements, but a general guideline is every few months or after washing.

Question 4: Are the seams on the backpack truly waterproof, or merely water resistant?

The term “water resistant” typically indicates that the seams are treated to repel water but may not be entirely impervious to water penetration under prolonged or intense exposure. Taped or sealed seams offer a higher level of protection compared to standard stitched seams.

Question 5: What is the expected lifespan of a Vera Bradley water resistant backpack under normal usage conditions?

Lifespan is contingent on usage frequency, care, and environmental factors. With proper care and maintenance, a well-constructed backpack can provide several years of reliable service. However, signs of wear, such as fading, fraying, or compromised water resistance, may necessitate replacement over time.

Question 6: Does the warranty cover water damage to items stored inside the backpack?

Warranty coverage typically addresses manufacturing defects and does not extend to damage resulting from misuse, accidents, or environmental factors, including water damage. Refer to the specific warranty terms and conditions for clarification.

The answers above offer guidance on understanding and maintaining the protective qualities of the water-resistant features. Proper use and preventative care will substantially prolong the product’s performance.

The concluding section will summarize the key considerations when selecting and maintaining this product.

Conclusion

This exploration has addressed the multifaceted characteristics of the “vera bradley water resistant backpack.” The analysis encompassed fabric durability, seam construction, zipper quality, coating effectiveness, and design aesthetics, underscoring their individual and collective contributions to the product’s performance. Maintenance protocols and responses to frequently asked questions were also provided, aimed at extending the product’s lifespan and optimizing its utility.

In light of the information presented, prospective purchasers are urged to critically evaluate their specific needs and usage scenarios before making a selection. The long-term value of the product is inextricably linked to informed decision-making and diligent adherence to recommended care practices. Prioritizing these factors ensures that the investment aligns with expectations of durability, functionality, and protection against environmental elements.

![Charming Mickey: Vera Bradley Backpack [Deals!] Ultimate Backpack Traveler Guide: Tips, Destinations & Budget Hacks Charming Mickey: Vera Bradley Backpack [Deals!] | Ultimate Backpack Traveler Guide: Tips, Destinations & Budget Hacks](https://backpack-traveler.com/wp-content/uploads/2025/10/th-516-300x200.jpg)