The structural component within load-bearing rucksacks provides support and distributes weight effectively. An example of such a component is a rigid internal skeleton made of metal or composite materials, designed to transfer the load from the pack to the wearer’s hips and legs.

This element significantly enhances carrying comfort and stability, especially when transporting heavier loads over extended periods. Historically, it evolved from simple external structures to more sophisticated internal designs that improve balance and allow for a closer fit to the body, optimizing biomechanics.

The following sections will delve into the different types of these components, their construction materials, the advantages and disadvantages of each design, and how to select the most suitable option for various backpacking and hiking activities.

Considerations for Rucksack Structural Support Selection

The selection of an appropriate support structure for a rucksack is paramount for ensuring comfortable and efficient load carriage. Several factors merit careful consideration prior to purchase.

Tip 1: Assess Load Requirements: Evaluate the total weight and volume anticipated for typical excursions. Higher weight necessitates a more robust and rigid structure, such as those constructed from aluminum or high-density polyethylene.

Tip 2: Evaluate Torso Length: Measure torso length accurately to ensure proper structure sizing. An ill-fitting component will not effectively transfer weight to the hips, resulting in discomfort and potential injury.

Tip 3: Examine Hip Belt Design: Scrutinize the hip belt’s padding, adjustability, and contour. An effective hip belt is crucial for distributing the majority of the load to the lower body.

Tip 4: Analyze Structure Material: Differentiate between the properties of various construction materials. Aluminum offers durability and rigidity, while composite materials provide a balance of strength and weight.

Tip 5: Consider Ventilation: Assess the ventilation provided by the structure’s design. Adequate airflow between the structure and the wearer’s back minimizes perspiration and enhances comfort in warm climates.

Tip 6: Evaluate Adjustability: Determine the extent to which the structure is adjustable. Adjustability allows for fine-tuning the fit to accommodate varying loads and body shapes.

Tip 7: Research Specific Activities: Tailor the selection to the intended activities. Mountaineering may require a more streamlined and stable structure compared to general hiking.

Selecting the optimal structure demands a thorough understanding of individual needs and the characteristics of available options. Prioritizing load requirements, fit, and material properties will contribute to a more comfortable and efficient outdoor experience.

The subsequent sections will provide a detailed analysis of specific structure types, including internal, external, and frameless designs, along with a comparative evaluation of their respective advantages and disadvantages.

1. Load Distribution

Effective load distribution is a primary function facilitated by the structural support system in a rucksack. The interaction between the pack and its underlying structure dictates how weight is transferred to the wearer, influencing comfort, stability, and overall efficiency during movement.

- Hip Belt Interface

The hip belt serves as the primary load-bearing interface. The structural component is engineered to efficiently transfer a significant portion of the carried weight onto the hip belt. For instance, a well-designed internal support system will channel upwards of 80% of the load to the hips, minimizing stress on the shoulders and back. Inadequate transfer can result in excessive shoulder strain and compromised balance, particularly on uneven terrain.

- Vertical Stays and Load Lifters

Vertical stays, often constructed from aluminum or composite materials, provide vertical rigidity and prevent the pack from collapsing or sagging. Load lifter straps, connecting the top of the pack to the shoulder straps, fine-tune the angle of pull and further enhance load distribution. These elements work in concert to maintain a stable center of gravity and prevent the load from shifting excessively during dynamic movements. Failure of a stay can lead to uneven weight distribution and discomfort.

- Frame Geometry and Torso Length Adjustment

The geometry of the structural component is designed to align with the natural curvature of the spine and promote proper posture. Adjustable torso length features allow users to customize the fit, ensuring optimal load transfer regardless of individual body proportions. A properly fitted structure will distribute weight evenly across the hips and shoulders, minimizing pressure points and reducing the risk of injury. Improper fit can lead to localized stress and musculoskeletal strain.

- Pack Volume and Compartmentalization

The internal organization and compartmentalization of a rucksack contribute to load distribution. Heavy items should be positioned closer to the wearer’s center of gravity and within the main compartment. External pockets and attachment points should be used strategically to maintain balance and prevent the load from shifting. Unevenly distributed weight can negatively impact stability and increase the risk of falls, especially in challenging environments.

The structural component, therefore, acts as an integrator, ensuring that the weight within the rucksack is managed effectively and transferred optimally to the wearer. Different structure types internal, external, or frameless approach this challenge with varying degrees of success, influenced by factors such as material properties, design complexity, and adjustability. The selection of an appropriate structure should consider the anticipated load, the wearer’s body type, and the intended activity to maximize comfort and minimize the risk of injury.

2. Torso Length

Torso length, the distance from the seventh cervical vertebra (C7) at the base of the neck to the iliac crest (the top of the hip bone), is a critical measurement directly impacting the efficacy of a rucksack structural support system. The structural component is designed to transfer weight from the shoulders to the hips, a process contingent upon proper torso length alignment. A mismatch between the user’s torso length and the specified torso range of the structural element leads to inefficient weight distribution, causing discomfort, fatigue, and potential injury. For example, if the structure is too long for the individual, the hip belt will sit too low, transferring weight to the lumbar region rather than the hips, resulting in back pain. Conversely, a structure that is too short will cause the hip belt to ride too high, placing undue stress on the shoulders and upper back.

Adjustable structural designs address the inherent variability in human anatomy. These designs incorporate mechanisms allowing users to modify the effective torso length of the support system. This adjustability enables a more precise fit, optimizing weight transfer and enhancing carrying comfort. An instance of this adjustability is seen in the integration of sliding shoulder harness systems or adjustable hip belt attachments, both designed to accommodate a range of torso lengths within a single pack size. The absence of such adjustability necessitates careful measurement and selection of a specific structure size to match the individual’s torso dimensions.

Understanding the relationship between torso length and the structural component is thus paramount for rucksack selection. Failure to account for this fundamental measurement negates the benefits of advanced structural designs and compromises the wearer’s physical well-being. Proper fit ensures weight is efficiently distributed to the body’s strongest muscle groups, allowing for comfortable and sustainable load carriage over extended periods. This understanding is particularly relevant in demanding activities like mountaineering or long-distance hiking, where prolonged exertion can exacerbate the consequences of an ill-fitting structure. Therefore, accurate torso measurement and diligent structure selection are essential for maximizing performance and minimizing the risk of injury.

3. Material Strength

Material strength is a fundamental consideration in the design and performance of any structural element. Within the context of load-bearing rucksacks, the strength of the materials used in the structural element dictates the overall capacity, durability, and reliability of the pack under varied and demanding conditions.

- Yield Strength and Load Capacity

Yield strength, the point at which a material begins to deform permanently, directly influences the load capacity of the structural component. Materials with higher yield strengths, such as certain aluminum alloys or reinforced polymers, can withstand heavier loads without permanent deformation. This characteristic is particularly critical for backpacking or mountaineering rucksacks designed to carry substantial weight for extended periods. Exceeding the yield strength can compromise the structural integrity of the pack, leading to failure and potential equipment loss.

- Tensile Strength and Durability

Tensile strength, the maximum stress a material can withstand before breaking, is a key determinant of the structural component’s long-term durability. Materials with high tensile strengths, like steel or certain composite materials, are more resistant to tearing or fracture under stress. This resistance is essential for rucksacks exposed to abrasive environments or subjected to repeated stress cycles during hiking or climbing. A structural element with inadequate tensile strength is prone to damage, shortening the lifespan of the pack.

- Stiffness and Load Transfer

The stiffness, or resistance to bending, of the material affects how efficiently the structural component transfers the load from the pack to the wearer’s hips and shoulders. Stiffer materials, such as aluminum or carbon fiber, provide a more rigid support system, distributing weight evenly and minimizing pressure points. This enhanced load transfer improves comfort and reduces the risk of strain or injury. Conversely, a flexible structure may not adequately support the load, leading to uneven weight distribution and discomfort.

- Fatigue Resistance and Longevity

Fatigue resistance, the ability of a material to withstand repeated cycles of stress without failure, is crucial for the longevity of the structural element. Materials with high fatigue resistance, like certain grades of steel or titanium, can endure numerous loading and unloading cycles without significant degradation. This property is particularly important for rucksacks used frequently or in demanding environments, as repeated stress can weaken the structural element over time. A structural component with poor fatigue resistance is likely to fail prematurely, requiring repair or replacement.

The selection of materials with appropriate strength characteristics is thus paramount in the design of rucksacks. Different materials offer varying combinations of yield strength, tensile strength, stiffness, and fatigue resistance, each influencing the pack’s overall performance and durability. Engineers must carefully consider these factors to optimize the structural component for the intended use, balancing strength with weight, cost, and other design constraints. The structural element’s function as the backbone of the pack demands that material strength be a central focus during development and manufacturing.

4. Weight Management

Effective weight management is intrinsically linked to the design and selection of a rucksack structural support. The structural element’s ability to distribute and support the load significantly influences the perceived weight and the user’s physical strain. Optimizing this relationship is critical for enhancing comfort and minimizing the risk of injury, particularly during extended excursions.

- Frame Material and Total Pack Weight

The material composition of the structural component directly impacts the overall weight of the rucksack. Utilizing lightweight materials, such as aluminum alloys or composite polymers, reduces the base weight of the pack, allowing for a greater carrying capacity without significantly increasing the burden on the user. For instance, a transition from a steel structure to an aluminum alloy counterpart can reduce the pack’s weight by several pounds, a noticeable difference during prolonged hiking. This reduction in weight can translate to increased endurance and reduced fatigue.

- Load Distribution Efficiency and Perceived Weight

A well-designed structural component effectively distributes the load across the wearer’s body, primarily to the hips and legs, minimizing the strain on the shoulders and back. This efficient distribution reduces the perceived weight of the pack, making it feel lighter than its actual mass. Ineffective load distribution, conversely, concentrates the weight on specific pressure points, exaggerating the perceived weight and leading to discomfort and potential injury. Therefore, a structural design optimized for load transfer is crucial for managing the perceived weight of the pack.

- Adjustability and Personalized Weight Management

Adjustable structural components, such as those with adjustable torso lengths or hip belt configurations, allow users to customize the fit of the rucksack to their individual body dimensions. This personalized fit optimizes load distribution and enhances stability, contributing to more effective weight management. A properly adjusted structure ensures that the weight is evenly distributed across the body, reducing localized pressure and promoting a more comfortable and efficient carrying experience. Lack of adjustability can compromise weight distribution and increase the risk of strain.

- Frame Geometry and Stability under Load

The geometry of the structural component influences the pack’s stability, particularly under heavy loads. A well-designed structure maintains the pack’s center of gravity close to the wearer’s body, minimizing sway and improving balance. This stability contributes to more efficient weight management, as the user expends less energy compensating for shifting loads. An unstable pack, conversely, requires constant adjustments and increased muscular effort to maintain balance, exacerbating fatigue and increasing the risk of falls. Therefore, structural geometry optimized for stability is a critical aspect of weight management.

The relationship between the structural component and effective weight management is multifaceted, encompassing material selection, load distribution, adjustability, and stability. A holistic approach to structural design, considering these interdependencies, is essential for creating rucksacks that minimize physical strain and maximize carrying efficiency. Continued advancements in materials and structural engineering promise to further refine this relationship, enabling users to carry heavier loads with greater comfort and reduced risk of injury.

5. Stability Control

Stability control, in the context of load-bearing rucksacks, refers to the system’s ability to maintain a stable center of gravity and minimize sway, particularly when traversing uneven terrain or engaging in dynamic movements. The structural element is integral to this control, influencing how the pack responds to external forces and how effectively the carried load is managed.

- Frame Rigidity and Torso Twist

The rigidity of the structural support significantly impacts resistance to torso twist. A stiffer structure, often achieved through the use of aluminum or composite materials, reduces the tendency for the pack to sway independently of the wearer’s body. This reduction minimizes the energy expended on maintaining balance and reduces the risk of losing footing on unstable surfaces. A more flexible design, conversely, may permit greater freedom of movement but can compromise stability, especially with heavier loads.

- Load Placement and Center of Gravity

The geometry of the structural element influences the placement of the load and, consequently, the overall center of gravity of the pack. By positioning the load closer to the wearer’s back, the structural design minimizes the moment of inertia and reduces the rotational forces that can destabilize the wearer. Strategic compartmentalization within the pack, guided by the frame design, further refines load placement to optimize stability. An elevated or poorly positioned load increases the risk of imbalance and falls.

- Hip Belt Integration and Pelvic Stability

The interface between the structural element and the hip belt plays a crucial role in stabilizing the load relative to the wearer’s pelvis. A well-integrated system transfers a significant portion of the load directly to the hips, effectively anchoring the pack and minimizing vertical movement. The shape, padding, and adjustability of the hip belt further enhance stability by conforming to the contours of the pelvis and preventing slippage. Insufficient hip belt integration compromises stability and increases stress on the shoulders and back.

- Suspension System and Dynamic Balance

The suspension system, including the shoulder straps and load lifters, works in conjunction with the structural component to maintain dynamic balance during movement. The adjustability of these elements allows users to fine-tune the fit and distribute the load effectively, minimizing sway and enhancing stability, particularly on uneven terrain. A properly adjusted suspension system ensures that the pack remains stable and balanced, even when the wearer is actively moving or navigating challenging obstacles. Improper suspension adjustments can lead to instability and increase the risk of falls.

These factors, working in concert, determine the overall stability control of the rucksack. The structural element functions as the central organizing component, dictating how the load is managed and how the pack interacts with the wearer’s body during movement. By optimizing the structural design for rigidity, load placement, hip belt integration, and suspension system performance, rucksacks can provide enhanced stability control, minimizing physical strain and reducing the risk of accidents in demanding environments.

6. Design Variations

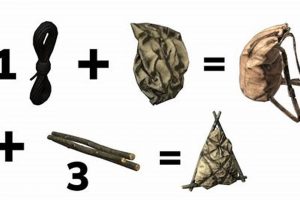

Variations in structural design directly influence the performance characteristics of load-bearing rucksacks. The selected configuration is not arbitrary; it arises from specific performance requirements, load capacities, and intended usage scenarios. For instance, internal structures, characterized by their concealment within the pack body, offer a streamlined profile favored in activities such as mountaineering, where minimizing snag hazards is paramount. This design choice has a direct effect: improved maneuverability in constricted environments. Conversely, external structures, with their visible frames, often provide superior ventilation and the capacity to carry awkwardly shaped or oversized loads, attributes valued in extended expeditions. The selection of one design over another, therefore, stems from a considered analysis of the anticipated demands.

The evolution of structural design reflects ongoing efforts to optimize weight distribution, stability, and comfort. Frameless rucksacks, representing a minimalist approach, are suitable for light loads and situations where pack weight is a critical concern. However, their efficacy diminishes as load increases, making them unsuitable for demanding multi-day treks. Hybrid designs, incorporating elements of both internal and external structures, attempt to strike a balance between load-carrying capacity, ventilation, and profile. An example of such a hybrid is a pack featuring an internal frame with external attachment points, offering both streamlined load carriage and the flexibility to secure additional gear. The selection process necessitates an understanding of the trade-offs inherent in each design.

Understanding the connection between design variations and performance characteristics is crucial for informed rucksack selection. Factors such as intended activity, load weight, and environmental conditions dictate the optimal choice. Neglecting this understanding can lead to compromised performance, discomfort, and potential injury. The diversity in structural designs reflects the multifaceted nature of load-bearing requirements, demanding a comprehensive approach to evaluation and selection. Ultimately, the effectiveness of any particular design is contingent upon its suitability for the specific task at hand.

Frequently Asked Questions

The following section addresses common inquiries regarding rucksack structural support elements. The answers provided aim to offer clarity and informed understanding.

Question 1: What constitutes a rucksack structural element?

A rucksack structural element is a load-bearing component within a backpack, designed to transfer weight from the shoulders to the hips. This element provides rigidity and support, enabling the efficient carriage of heavy loads.

Question 2: What materials are typically employed in the manufacture of these components?

Common materials include aluminum alloys, steel, composite polymers, and, in some cases, titanium. The selection of material is dictated by factors such as strength-to-weight ratio, durability, and cost considerations.

Question 3: How does torso length influence the selection of a structural element?

Torso length is a critical measurement. A structural element must correspond to the user’s torso length to ensure proper weight distribution. An ill-fitting component can lead to discomfort, strain, and potential injury.

Question 4: What are the primary advantages of an internal structure?

Internal structures offer a streamlined profile, minimizing snag hazards in confined environments. They typically provide better load stabilization and are suitable for a wide range of activities.

Question 5: What are the primary advantages of an external structure?

External structures often provide superior ventilation and are capable of accommodating larger or awkwardly shaped loads. They may also offer greater adjustability for specific body types.

Question 6: How should one maintain a rucksack structural element?

Maintenance typically involves inspecting the component for damage, cleaning it to remove dirt and debris, and ensuring that all fasteners are secure. Proper storage, away from extreme temperatures and humidity, is also recommended.

The structural element forms the backbone of the rucksack and significantly influences its performance and user comfort. Understanding these key aspects aids in informed selection and responsible usage.

The subsequent section will delve into advanced topics regarding structural engineering in rucksacks, encompassing aspects such as dynamic load analysis and finite element modeling.

Backpack Frame

This exploration has established the paramount role of the backpack frame in load carriage systems. The analysis encompassed material strength, weight management, stability control, and design variations, underscoring the interplay of these elements in determining a rucksack’s overall efficacy. A thorough understanding of torso length considerations and load distribution mechanics remains crucial for optimizing performance and minimizing user strain.

Continued research and engineering advancements will undoubtedly refine structural designs and material compositions. Vigilant evaluation of individual needs and careful consideration of available technologies are therefore essential for ensuring the selection of appropriate and reliable equipment, particularly in demanding environments. The backpack frame is not merely a component; it is the foundation upon which safe and efficient load carriage depends.