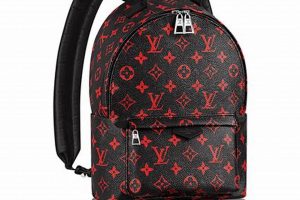

Small, personalized carrying solutions offer a compact and adaptable alternative to traditional bags. These items, often fabricated from a variety of materials, can be tailored to reflect individual aesthetic preferences or to serve specific functional requirements. An example includes a scaled-down rucksack adorned with a company logo, utilized for promotional distribution at a marketing event.

The demand for these personalized articles stems from their practicality and versatility. They provide a convenient method for transporting essential items while maintaining a streamlined profile. Historically, the evolution of carrying devices has progressed from rudimentary pouches to increasingly sophisticated designs, reflecting changing societal needs and technological advancements. The emergence of smaller, customizable options represents a continuation of this trend, emphasizing personalization and portability.

The following sections will delve into the various aspects of creating these unique items, including design considerations, material selection, and the manufacturing processes involved. Further discussion will address the diverse applications and potential markets for these bespoke personal accessories.

Considerations for Acquisition and Design

The process of procuring or designing personalized small backpacks involves careful planning and attention to detail. These guidelines offer insights into optimizing the creation and utilization of such items.

Tip 1: Define Purpose: Clearly delineate the intended use case. Is it for promotional purposes, retail sale, or internal company use? This will guide subsequent design and material choices. For instance, a promotional piece may prioritize visual impact over durability, while a retail item necessitates a higher degree of robustness.

Tip 2: Material Selection: Opt for materials that align with the intended application and budget. Durable fabrics like nylon or polyester are suitable for frequent use, while more premium materials such as canvas or leather offer a higher perceived value. Evaluate factors like water resistance, tear strength, and printability.

Tip 3: Customization Options: Explore available customization techniques. Screen printing is a cost-effective solution for simple designs, whereas embroidery provides a more textured and premium finish. Consider direct-to-garment printing for complex, full-color graphics. Ensure the chosen method is compatible with the selected material.

Tip 4: Size and Compartmentalization: Determine the optimal dimensions and internal configuration. A well-designed interior should include pockets and dividers to facilitate organization. Consider the types of items users are likely to carry and design accordingly.

Tip 5: Hardware and Accessories: Pay attention to the quality of zippers, buckles, and straps. Inferior hardware can detract from the overall quality and durability of the product. Opt for reliable brands and materials that can withstand regular use.

Tip 6: Ergonomics and Comfort: Evaluate the design from a user perspective. Padded shoulder straps and a breathable back panel can enhance comfort during extended wear. Adjustability is also crucial to accommodate different body sizes.

Tip 7: Compliance and Safety: Ensure that materials and manufacturing processes comply with relevant safety standards and regulations. This is particularly important for items intended for children. Verify that materials are free from harmful substances such as lead and phthalates.

Thoughtful planning and meticulous execution are essential for creating successful and valuable personalized miniature backpacks. By adhering to these guidelines, one can maximize the impact and utility of these versatile carrying solutions.

The next section will elaborate on the potential challenges and mitigation strategies involved in large-scale production and distribution of these articles.

1. Design Flexibility

Design flexibility, in the context of individualized small backpacks, directly correlates with the capacity to fulfill diverse consumer needs and preferences. It is the pivotal element that allows a standardized product to be adapted into a bespoke item, enhancing its market appeal and perceived value.

- Adaptable Aesthetics

Adaptable aesthetics represent the range of customizable visual elements available. This encompasses color schemes, graphic overlays, and the incorporation of personalized imagery. A company distributing these items as promotional material might opt for a design that precisely matches its corporate branding, while an individual consumer might select a pattern that reflects personal interests or affiliations. The ability to manipulate these aesthetic variables is crucial for achieving design flexibility.

- Modular Component Integration

Modular component integration refers to the capacity to add or remove features based on specific requirements. This could involve detachable pockets, adjustable straps, or interchangeable panels. For instance, a user intending to utilize the item for outdoor activities might select a model with detachable water bottle holders and a reinforced bottom. This modularity allows the core product to be adapted for diverse use cases, thereby expanding its applicability.

- Material Versatility

Material versatility is the availability of various fabric options, each offering distinct properties in terms of durability, texture, and water resistance. The choice of material significantly impacts the item’s suitability for different environments and purposes. A backpack intended for daily commuting might benefit from a water-resistant nylon fabric, while one designed for fashion purposes could utilize a more aesthetically pleasing, but less durable, material like faux leather. Material selection is therefore a vital component of design flexibility.

- Structural Modification

Structural modification involves altering the physical dimensions and internal layout of the article. This could range from adjusting the overall size to reconfiguring internal compartments. A photographer, for example, might require a design with specific padded compartments for lenses and equipment, while a student might prefer a layout optimized for textbooks and notebooks. The ability to modify the internal structure allows the article to be tailored to specialized carrying needs.

The interconnectedness of adaptable aesthetics, modular component integration, material versatility, and structural modification defines the overall design flexibility. A product offering a wide range of options within these categories is better positioned to meet the diverse and evolving needs of the market, thereby enhancing its appeal and competitiveness. The implementation of these features directly influences the article’s success as a personalized accessory.

2. Material Durability

Material durability is a critical determinant of the longevity and utility of individualized small backpacks. The inherent properties of the selected material directly influence its resistance to wear, tear, and environmental degradation. A direct correlation exists between material quality and the lifespan of the carrying device. For instance, a miniature backpack constructed from a tightly woven, high-denier nylon will exhibit superior resistance to abrasion and tearing compared to one made from a loosely woven, lower-denier polyester. This enhanced durability translates to extended usability, reduced replacement frequency, and ultimately, increased value for the end user. Scenarios such as daily commuting, outdoor excursions, and prolonged use in demanding environments underscore the importance of selecting robust materials capable of withstanding significant stress. Failure to prioritize material durability can result in premature product failure, leading to customer dissatisfaction and potential brand damage. A practical understanding of material properties, therefore, is paramount in the design and manufacture of these personalized items.

The selection of materials also has implications for maintenance and care. More durable fabrics often exhibit greater resistance to staining, fading, and water damage. This reduces the need for frequent cleaning and specialized treatment, further extending the product’s lifespan. Consider, for example, a miniature backpack intended for use by children. Spills and stains are inevitable. Choosing a material that is easily wiped clean and resistant to permanent discoloration simplifies maintenance and ensures the item remains presentable over time. In addition, resistance to UV degradation is essential for items intended for outdoor use, preventing fading and weakening of the fabric. Consequently, decisions regarding material selection should encompass not only immediate performance characteristics but also long-term maintenance requirements.

In summation, material durability represents a fundamental aspect of design and manufacturing processes of personalized carrying articles. It impacts product longevity, maintenance requirements, and overall value. The challenges associated with ensuring adequate material durability often involve balancing cost considerations with performance requirements. However, prioritizing robust materials, tailored to the intended application, is essential for creating durable, reliable, and ultimately, successful articles. This focus on material quality contributes directly to positive user experiences and brand reputation.

3. Size Optimization

Size optimization in the context of individualized small backpacks directly impacts their functionality and market appeal. The dimensions of the bag must align with the intended use case and target audience to maximize utility and user satisfaction. A bag that is too small will fail to accommodate essential items, rendering it impractical. Conversely, an excessively large bag negates the benefits of a compact design, sacrificing portability and convenience. Thus, striking a balance between internal capacity and external dimensions is crucial. For example, a miniature backpack designed for carrying a smartphone, wallet, and keys requires a significantly smaller volume than one intended for transporting a tablet, water bottle, and snacks. Understanding these needs is essential for effective optimization.

The practical significance of size optimization extends beyond simple carrying capacity. It influences the overall ergonomic design, weight distribution, and ease of maneuverability. A poorly optimized bag can lead to discomfort, strain, and reduced user mobility. Consider the example of miniature backpacks designed for children. An excessively large bag, even if it can accommodate all necessary school supplies, can place undue stress on a child’s developing spine. A more compact and lightweight design, tailored to the child’s physical capabilities, promotes comfort and prevents potential health issues. Similarly, a strategically designed interior with well-placed compartments can optimize space utilization and prevent items from shifting during movement. This, in turn, contributes to a more stable and comfortable carrying experience.

In conclusion, size optimization represents a multifaceted consideration in the design and manufacture of individualized small backpacks. It directly affects their functionality, ergonomic properties, and overall suitability for the intended purpose. Effective size optimization requires a thorough understanding of target user needs, a careful selection of materials, and a strategic arrangement of internal compartments. By prioritizing these aspects, manufacturers can create articles that are both practical and appealing, maximizing user satisfaction and market success. Balancing these factors presents a persistent design challenge, yet remains a critical element in the creation of successful and desirable compact carrying solutions.

4. Target Audience

The identification and understanding of the intended consumer base is paramount in the design, production, and marketing of individualized small backpacks. The target audience dictates critical design parameters, material choices, and ultimately, the perceived value and market success of the product. A generalized approach, neglecting specific demographic characteristics, often results in suboptimal product development and diminished market penetration.

- Age and Developmental Stage

Age and developmental stage significantly influence size, features, and safety considerations. For preschool-aged children, smaller dimensions, lightweight materials, and enhanced safety features, such as reflective elements and secure closures, are crucial. Teenagers may prioritize style, brand recognition, and functionality, such as designated compartments for electronic devices. Adults might seek a balance of durability, professional appearance, and practical organization. Ignoring these age-related needs can lead to products that are unsuitable or unappealing to the intended user, decreasing potential sales.

- Lifestyle and Activities

Lifestyle and typical activities directly inform the functional requirements. A consumer leading an active outdoor lifestyle may require a rugged, water-resistant backpack with adjustable straps and specialized compartments for hydration packs or trekking poles. An urban commuter might prioritize a sleek, minimalist design with a focus on security features, such as hidden pockets and slash-resistant materials. Understanding the daily routines and activities of the target demographic ensures that the design aligns with their practical needs, enhancing product utility and desirability.

- Socioeconomic Factors

Socioeconomic factors influence purchasing power and aesthetic preferences. A higher-income demographic may be willing to invest in premium materials, designer branding, and advanced features. A more budget-conscious segment might prioritize affordability, durability, and practical functionality over aesthetic embellishments. Tailoring product designs and marketing strategies to align with the socioeconomic realities of the target demographic is essential for optimizing sales and market penetration.

- Cultural and Regional Considerations

Cultural and regional variations impact color preferences, design aesthetics, and acceptable levels of ornamentation. A design that is highly popular in one region or culture may be considered inappropriate or undesirable in another. Understanding these nuances requires diligent market research and a sensitivity to cultural norms and traditions. Adapting designs and marketing campaigns to resonate with specific cultural and regional preferences can significantly enhance product acceptance and sales within those markets.

In conclusion, the multifaceted understanding of the target audience forms the foundation upon which successful individualized miniature backpack designs are built. Age, lifestyle, socioeconomic factors, and cultural considerations collectively shape the ideal product profile. Neglecting any of these dimensions can result in design flaws, marketing missteps, and ultimately, a failure to connect with the intended consumer base. Detailed market research and a customer-centric design approach are therefore indispensable for achieving market success in this competitive sector.

5. Branding Integration

Branding integration, when strategically applied to individualized small backpacks, transcends mere logo placement; it represents a crucial mechanism for enhancing brand visibility and fostering customer loyalty. The miniature backpack, acting as a mobile advertisement, extends brand reach into diverse environments, from urban landscapes to recreational settings. The efficacy of branding integration hinges on the harmonious blending of brand elements with the product’s design, ensuring that the logo, color palette, and overall aesthetic complement, rather than detract from, the bag’s functionality and appeal. A poorly executed branding strategy, characterized by oversized or garish logos, can diminish the perceived value of the product and negatively impact brand perception. Conversely, a subtle and sophisticated approach can transform the backpack into a desirable accessory, subtly reinforcing brand awareness with each use. For instance, a tech company might utilize a minimalist logo and a color scheme aligned with its corporate identity on a sleek, functional miniature backpack, appealing to its target demographic of tech-savvy consumers.

The practical significance of effective branding integration extends to marketing and promotional campaigns. Miniature backpacks, customized with a company logo and distributed as promotional items at trade shows or corporate events, serve as tangible reminders of the brand. The utility and portability of these items ensure sustained visibility, as recipients are likely to use them regularly. Furthermore, branding integration allows companies to create a cohesive brand image across various touchpoints. If the design of the custom backpack aligns with the brand’s overall marketing materials and website, it reinforces brand consistency and strengthens brand recognition. Companies such as outdoor apparel retailers often utilize custom miniature backpacks, adorned with their logo and featuring durable materials, as promotional gifts or retail items. This strategy effectively targets their core audience and reinforces their brand image of quality and outdoor adventure.

In conclusion, branding integration is not merely an optional add-on but an intrinsic component of individualized miniature backpack design. A strategic approach to branding, one that prioritizes subtle elegance, design cohesion, and a clear understanding of the target audience, can transform the item into a powerful marketing tool. Challenges associated with branding integration include balancing brand visibility with aesthetic appeal, selecting appropriate customization techniques, and ensuring consistent brand representation across all promotional materials. However, the benefits of successful branding integration, including increased brand awareness, enhanced customer loyalty, and a strengthened brand image, make it a worthwhile investment for companies seeking to maximize their marketing reach and impact.

6. Production Scalability

Production scalability represents a critical factor influencing the feasibility and profitability of offering individualized miniature backpacks. The capacity to efficiently increase production volume in response to rising demand directly affects unit cost, lead times, and overall market competitiveness. A lack of scalability can result in missed sales opportunities, increased manufacturing expenses, and potential customer dissatisfaction due to order delays. For example, a small-scale manufacturer relying on manual processes may struggle to fulfill a large order for custom-designed backpacks from a national retailer, leading to contract cancellation and financial losses. Conversely, manufacturers employing automated production lines and streamlined supply chains possess the agility to accommodate fluctuating demand, ensuring consistent product availability and competitive pricing.

The incorporation of scalable manufacturing techniques allows for the economic production of both standardized and customized miniature backpacks. Digital printing technologies, such as direct-to-garment printing, enable on-demand customization without requiring large minimum order quantities, facilitating personalized designs at scale. Modular assembly processes, where components are pre-fabricated and assembled according to specific customer requirements, streamline production and reduce lead times. Supply chain management plays a crucial role; manufacturers with diversified sourcing options can mitigate the risk of material shortages and maintain consistent production levels even in the face of disruptions. Apparel companies such as Vistaprint or CustomInk utilize digital printing and efficient logistics to provide scalable customization options, demonstrating the application of these principles.

In summary, production scalability is inextricably linked to the success of any venture involving individualized miniature backpacks. It impacts pricing, delivery speed, and the ability to meet evolving market demands. The challenges associated with achieving scalability include optimizing manufacturing processes, managing supply chains effectively, and investing in adaptable technologies. However, the rewards of a scalable production model include enhanced profitability, improved customer satisfaction, and a strengthened competitive position within the dynamic market for personalized accessories. Therefore, a strategic focus on production scalability is essential for sustained growth and success.

Frequently Asked Questions

This section addresses common inquiries regarding personalized small backpacks, providing detailed and factual answers to assist in informed decision-making.

Question 1: What is the typical lead time for a large order of personalized small backpacks?

Lead times vary depending on order size, customization complexity, and manufacturer capacity. Generally, expect a lead time of 2 to 8 weeks for bulk orders. Inquire with specific manufacturers to obtain precise estimates, accounting for potential variations in production schedules.

Question 2: What are the most durable material options for custom miniature backpacks intended for frequent use?

High-denier nylon, polyester, and canvas offer excellent durability for frequent use. Nylon provides superior abrasion resistance, while polyester offers good water resistance. Canvas offers a blend of durability and aesthetic appeal. The specific choice depends on budget and intended application.

Question 3: Is it possible to order a sample before committing to a large production run?

Most reputable manufacturers offer sample production services. Requesting a sample allows for assessment of material quality, print accuracy, and overall design execution before proceeding with a full production run. This proactive step minimizes the risk of errors and ensures product satisfaction.

Question 4: What printing methods are best suited for intricate designs on custom small backpacks?

Direct-to-garment (DTG) printing offers superior detail and color accuracy for intricate designs. Screen printing is cost-effective for simpler designs with limited colors. Embroidery provides a textured and premium finish but is less suitable for highly detailed graphics.

Question 5: Are there minimum order quantities (MOQs) for custom small backpacks?

MOQs vary significantly among manufacturers. Some may offer low or no MOQs for digital printing, while others require higher minimums for screen printing or embroidery. Negotiate with manufacturers to determine the most cost-effective order quantity for specific needs.

Question 6: What safety certifications should be verified when sourcing custom small backpacks, particularly for children?

Ensure that materials and manufacturing processes comply with relevant safety standards, such as CPSIA (Consumer Product Safety Improvement Act) in the United States or EN71 in Europe. Verify that materials are free from harmful substances such as lead, phthalates, and other regulated chemicals.

This FAQ section aims to provide clarity on key considerations when ordering personalized small backpacks. Diligent research and communication with manufacturers are essential for achieving optimal results.

The subsequent segment will explore emerging trends and future directions in the realm of custom miniature carrying solutions.

Conclusion

This exploration of custom mini backpacks has illuminated diverse aspects, ranging from design considerations and material durability to production scalability and target audience alignment. The integration of branding, the nuances of size optimization, and adherence to safety standards were also examined. These individualized carrying solutions represent a confluence of functionality, aesthetics, and personalized expression within the broader landscape of accessory design.

As the demand for personalized and practical items continues to evolve, custom mini backpacks will likely occupy an increasingly prominent niche. Careful attention to design principles, material selection, and manufacturing processes remains paramount. Businesses and individuals seeking to leverage these items for promotional or personal use must prioritize quality and adaptability to achieve desired outcomes. The ongoing refinement of these aspects ensures the continued relevance and utility of custom mini backpacks in a dynamic market.

![Shop Stylish Mini Backpacks Brown & Beyond | [Brand Name] Ultimate Backpack Traveler Guide: Tips, Destinations & Budget Hacks Shop Stylish Mini Backpacks Brown & Beyond | [Brand Name] | Ultimate Backpack Traveler Guide: Tips, Destinations & Budget Hacks](https://backpack-traveler.com/wp-content/uploads/2026/02/th-207-300x200.jpg)