The subject of this analysis is a portable, insulated container designed for keeping items cold while being carried on the back. It combines the functionalities of a traditional cooler with the convenience of a backpack, allowing for hands-free transport of chilled goods. Examples of its use include outdoor adventures, picnics, and sporting events where maintaining the temperature of beverages and food is desired.

Such a container offers the benefit of mobility, enabling users to navigate various terrains while keeping perishables at the desired temperature. The insulated design minimizes heat transfer, preserving the coldness of the contents for an extended period. Historically, alternatives included rigid coolers, which lacked portability, or insulated bags without a supportive carrying system. This design offers a practical solution to a common need, blending cooling technology with ergonomic design.

The following sections will explore the construction materials, insulation technology, carrying capacity, and specific use-case scenarios relevant to this type of portable cooler, providing a detailed overview of its features and applications.

Optimizing Use

Maximizing the performance and longevity of portable insulated backpacks requires careful consideration of several key factors. The following guidelines provide practical recommendations for enhancing user experience and preserving product integrity.

Tip 1: Pre-Chill Contents: Before loading, ensure all items are adequately chilled. Introducing warm items significantly reduces the cooler’s ability to maintain a low temperature and shortens its effective cooling duration.

Tip 2: Utilize Ice Packs or Ice: Supplement the insulation with ice packs or ice to maintain optimal cooling. Consider the ice-to-content ratio; a higher proportion of ice to contents will result in extended cooling performance. Block ice generally melts slower than cubed ice.

Tip 3: Minimize Air Exposure: Every time the cooler is opened, warm air enters, raising the internal temperature. Limit the frequency and duration of openings to preserve cooling efficiency.

Tip 4: Proper Cleaning and Storage: After each use, thoroughly clean the interior and exterior to prevent the growth of bacteria or mold. Ensure the cooler is completely dry before storing it in a cool, dry place to prevent material degradation.

Tip 5: Avoid Overloading: Exceeding the stated weight capacity can compromise the integrity of the seams and carrying straps. Distribute weight evenly to prevent undue stress on any single point.

Tip 6: Protect from Direct Sunlight: While designed for outdoor use, prolonged exposure to direct sunlight can increase the internal temperature and potentially damage the exterior material. Seek shaded areas whenever possible.

Tip 7: Inspect Regularly: Periodically examine the cooler for any signs of wear and tear, such as frayed seams or punctures. Addressing minor issues promptly can prevent more significant damage and extend the cooler’s lifespan.

Adhering to these guidelines ensures that the portable insulated backpack functions optimally, providing reliable cooling performance and extended durability.

The subsequent sections will explore specific applications of this cooler type and delve into the technological advancements that continue to improve its effectiveness and convenience.

1. Insulation Efficiency

Insulation efficiency is a critical determinant of a portable insulated backpacks performance. The effectiveness of the insulation directly influences the duration for which the contents remain cold. A high insulation efficiency minimizes heat transfer between the internal environment and the external ambient temperature. This is achieved through the use of materials with low thermal conductivity and design features that reduce convection and radiation. For example, a backpack cooler employing closed-cell foam insulation will exhibit superior cold retention compared to one using open-cell foam, due to the reduced air circulation within the closed-cell structure. The consequences of low insulation efficiency include rapid temperature increase within the cooler, leading to spoilage of perishable goods and reduced effectiveness in maintaining beverage coolness.

Understanding the interplay between insulation materials and design is essential for users. Backpack coolers incorporating multiple layers of insulation, reflective barriers, and airtight closures exhibit enhanced insulation efficiency. Real-world applications, such as extended hiking trips or all-day outdoor events, necessitate high insulation performance to ensure the safe preservation of food and beverages. Consider two identical backpacks: one uses a single layer of standard foam, while the other uses a multi-layered composite with a reflective barrier. In a controlled test under identical ambient conditions, the latter will maintain a significantly lower internal temperature for a longer duration, demonstrating the practical significance of advanced insulation technology.

In summary, insulation efficiency represents a pivotal performance characteristic. Challenges in optimizing insulation involve balancing thermal performance with weight and bulk. Ongoing research focuses on developing lightweight, high-performance insulation materials that minimize environmental impact. A thorough comprehension of insulation principles enables informed consumer choices and facilitates the effective utilization of portable insulated backpacks for temperature-sensitive applications.

2. Carrying Comfort

Carrying comfort is a crucial design consideration in portable insulated backpacks. The inherent function of these devices necessitates mobility; therefore, the ease and comfort with which they can be carried directly impacts their utility and user satisfaction. Poor carrying comfort can lead to fatigue, strain, and reduced overall performance, negating the benefits of insulation and storage capacity. The weight of the contents, combined with the backpack’s own weight, can create significant stress on the wearer’s shoulders, back, and hips if the design does not adequately address ergonomic principles. For instance, a backpack with inadequately padded shoulder straps or a lack of a supportive hip belt will transfer the entire load to the shoulders, resulting in discomfort and potential injury during extended periods of use.

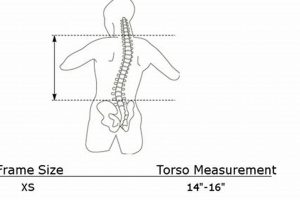

Effective carrying comfort is achieved through several key design elements. Padded shoulder straps, often incorporating breathable mesh, distribute weight more evenly and reduce friction. A hip belt transfers a portion of the load to the hips, alleviating stress on the shoulders and back, especially important for heavier loads. An adjustable torso length allows for customization to fit a range of body sizes, ensuring optimal weight distribution. A well-ventilated back panel minimizes perspiration and enhances comfort in warm conditions. Consider a scenario where two users are carrying identical loads in similar backpacks: the user with the backpack incorporating these ergonomic features will experience significantly less discomfort and fatigue compared to the user with a basic, unpadded design. The impact on endurance and overall user experience is substantial.

In summary, carrying comfort represents a fundamental aspect of insulated backpack design. Challenges in optimizing carrying comfort involve balancing ergonomic features with weight and cost considerations. Advanced designs incorporate load-transfer systems and custom-fit options to cater to diverse user needs. A focus on ergonomic design principles ensures that portable insulated backpacks provide a comfortable and efficient means of transporting chilled goods, enhancing their practicality and user appeal. The integration of these features directly correlates with the intended use case and target demographic of the product.

3. Material Durability

Material durability is a paramount consideration in the design and construction of portable insulated backpacks. The ability of the materials to withstand the rigors of outdoor use and repeated handling directly influences the lifespan and reliability of the cooler, determining its long-term value to the user.

- Fabric Resistance to Abrasion and Tearing

The outer fabric of the cooler is subjected to abrasion from contact with rough surfaces and potential tearing from sharp objects. High-denier nylon or polyester fabrics with reinforced stitching enhance resistance to these stresses. For example, a backpack cooler constructed from 1000D nylon will exhibit greater tear strength and abrasion resistance compared to one made from a lower-denier fabric. This translates to increased durability in demanding environments, preventing premature failure and maintaining the cooler’s structural integrity.

- Waterproof and Weatherproof Properties

Exposure to moisture is inevitable during outdoor use. Waterproof or water-resistant materials are essential to prevent water from penetrating the insulation and compromising its effectiveness. Coatings such as TPU (thermoplastic polyurethane) or DWR (durable water repellent) are often applied to fabrics to enhance their water resistance. A cooler lacking these properties can become waterlogged, increasing its weight and reducing its insulation capacity. Effective weatherproofing protects the contents from rain, snow, and humidity, ensuring they remain dry and at the desired temperature.

- Resistance to UV Degradation

Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade the materials, causing them to become brittle and prone to cracking. Fabrics treated with UV inhibitors exhibit greater resistance to this degradation. Consider two identical coolers, one exposed to direct sunlight daily and the other stored indoors: the unprotected cooler will show signs of fading and weakening over time, while the UV-protected cooler will maintain its structural integrity and color vibrancy for a longer duration. This is particularly important for users who frequently use the cooler in sunny environments.

- Insulation Material Integrity

The insulation material itself must be durable and resistant to compression and deformation. Closed-cell foam, such as EVA (ethylene-vinyl acetate), offers excellent insulation properties and maintains its shape under pressure. In contrast, open-cell foam can compress over time, reducing its insulation effectiveness. The selection of a durable insulation material ensures consistent thermal performance throughout the cooler’s lifespan, preventing the loss of cooling capacity due to material degradation.

These interconnected material properties define the overall durability and longevity of portable insulated backpacks. The selection of high-quality, durable materials is a critical factor in ensuring that the cooler can withstand the demands of outdoor use and provide reliable performance over an extended period. The investment in durable materials translates directly into a longer-lasting product and a greater return on investment for the user. The materials should not only be durable, but also sustainable to promote ethical consumption of goods.

4. Leakproof Design

The presence of a leakproof design is a crucial attribute in portable insulated backpacks, directly influencing their practicality and user satisfaction. Its absence compromises the intended functionality, potentially leading to damage to surrounding items and creating unsanitary conditions. The design focuses on preventing any liquid, either from melted ice or spilled contents, from escaping the confines of the cooler.

- Sealed Seam Construction

The method of joining the fabric panels is critical in preventing leaks. Sealed seams, achieved through welding or taping, create a barrier against liquid penetration. Traditional stitching leaves minute perforations that can allow leakage over time. The application of sealed seams ensures that even under pressure, liquids remain contained within the cooler. An example would be ultrasonic welding that creates a complete waterproof seam.

- Waterproof Zipper Systems

Zippers represent a potential point of failure in maintaining a leakproof environment. Specialized waterproof zippers, often incorporating a tight interlocking design and a protective coating, are employed to prevent water from seeping through the closure. Standard zippers offer minimal resistance to water ingress. Testing involves exposing the closed zipper to a stream of water or submersion to verify its integrity. Waterproof zippers that are on the higher end may be airtight as well.

- Liner Material Integrity

The inner lining of the cooler must be constructed from a non-porous, waterproof material capable of withstanding prolonged exposure to moisture. Materials such as TPU or heavy-duty vinyl are commonly used. A compromised liner, due to punctures or tears, negates the effectiveness of other leakproof measures. The integrity of the liner is essential for containing liquids and preventing saturation of the insulation. This requires the materials to be high performance with high heat resistance.

- Valve and Drainage Systems

Some coolers incorporate a drain valve to facilitate the removal of melted ice or excess water. The design and construction of this valve must ensure a watertight seal when closed. A poorly designed valve can be a significant source of leakage. Furthermore, the valve material must be resistant to corrosion and degradation from prolonged exposure to water. If any leakage occurs, it should be minimal.

The integration of these leakproof features is paramount in ensuring the reliable performance and user convenience of portable insulated backpacks. A robust leakproof design safeguards against messes and preserves the integrity of the cooler’s contents, enhancing its overall value and suitability for various applications, including those where hygiene and containment are critical.

5. Storage Capacity

Storage capacity is an intrinsic attribute of a portable insulated backpack, directly influencing its utility and intended application. This aspect determines the volume of items, whether beverages, food, or other temperature-sensitive goods, that the container can accommodate. Insufficient capacity restricts the user’s ability to carry adequate provisions, while excessive capacity may lead to unnecessary bulk and reduced portability. The storage capacity must align with the anticipated needs of the user, considering factors such as trip duration, number of participants, and types of items to be stored. For instance, a single-day hike requires less storage capacity than a multi-day camping excursion. The choice of storage capacity, therefore, is critical for optimizing the backpack’s functionality and user experience.

The design of the insulated backpack directly impacts the usable storage volume. The insulation material, while essential for maintaining temperature, occupies space within the cooler. Efficient design minimizes the insulation thickness without compromising thermal performance, thereby maximizing the internal storage area. Additionally, the presence of internal compartments or dividers can further enhance storage efficiency by organizing items and preventing them from shifting during transport. This organization, in turn, maximizes the potential storage capacity by ensuring efficient use of the available space. Consider a scenario where two identical coolers have the same external dimensions: the cooler with thinner, more efficient insulation and intelligent internal organization will provide a significantly larger usable storage volume.

In summary, storage capacity is a fundamental element in determining the suitability of a portable insulated backpack. Careful consideration of user needs, insulation efficiency, and internal organization is essential for optimizing storage capacity and maximizing the backpack’s utility. The ideal storage capacity balances the need for adequate provisions with the constraints of portability and overall backpack size. Challenges involve accurately predicting user needs and developing innovative designs that maximize usable storage volume without compromising thermal performance or ergonomic considerations. A well-chosen and efficiently designed storage capacity contributes significantly to the overall effectiveness and appeal of the insulated backpack, making it a practical and versatile solution for a wide range of activities.

Frequently Asked Questions About Portable Insulated Backpacks

The following questions address common concerns and provide clarity regarding the use, maintenance, and performance characteristics of portable insulated backpacks.

Question 1: What is the typical duration for which a portable insulated backpack can maintain a specific temperature?

The cooling duration is contingent upon several factors, including the ambient temperature, the initial temperature of the contents, the amount of ice or ice packs used, and the frequency with which the cooler is opened. Under optimal conditions, a high-quality cooler may maintain temperatures below 40F (4C) for up to 24 hours.

Question 2: What cleaning procedures are recommended for portable insulated backpacks?

Following each use, the interior should be cleaned with a mild soap and water solution. Thorough rinsing and drying are essential to prevent the growth of mold or bacteria. Abrasive cleaners or harsh chemicals should be avoided, as they may damage the liner or insulation.

Question 3: How does the insulation material affect the overall performance of the cooler?

The type and thickness of the insulation material significantly impact the cooler’s ability to maintain temperature. Closed-cell foam insulation, such as EVA or polyethylene, provides superior thermal resistance compared to open-cell foam. Thicker insulation layers offer enhanced performance, particularly in high-temperature environments.

Question 4: Are portable insulated backpacks suitable for air travel?

While the flexibility of these coolers offers advantages, adherence to airline regulations regarding size and weight restrictions is essential. Certain airlines may have specific policies concerning the transport of ice or ice packs. Consult the airline’s guidelines prior to travel.

Question 5: What is the recommended method for storing a portable insulated backpack when not in use?

The cooler should be thoroughly dried and stored in a cool, dry location away from direct sunlight. This prevents the growth of mold and mildew and protects the materials from UV degradation. Storing the cooler partially open may facilitate ventilation.

Question 6: What is the expected lifespan of a portable insulated backpack?

The lifespan is influenced by factors such as the quality of materials, frequency of use, and maintenance practices. With proper care, a well-constructed cooler can provide several years of reliable service. However, signs of wear and tear, such as seam separation or insulation degradation, may indicate the need for replacement.

These FAQs provide a foundational understanding of portable insulated backpacks. Adhering to these guidelines ensures optimal performance and prolonged product lifespan.

The subsequent section will explore the future trends and technological advancements shaping the evolution of this product category.

Conclusion

The preceding analysis has delineated the critical features and functionalities of the icemule backpack cooler. Its design integrates insulation efficiency, carrying comfort, material durability, leakproof construction, and sufficient storage capacity. These factors collectively determine its effectiveness in maintaining desired temperatures for extended periods while facilitating convenient transport in diverse environments. The importance of careful selection and maintenance has been emphasized to maximize its operational lifespan and ensure optimal performance.

As demand for portable cooling solutions persists, ongoing research and development efforts are poised to further enhance the icemule backpack cooler through innovative materials, improved insulation techniques, and optimized ergonomic designs. Stakeholders, from manufacturers to end-users, should remain cognizant of these advancements to leverage the full potential of this technology and ensure its responsible application in meeting evolving needs for temperature-controlled transport.