Items combining elements from Walt Disney Company intellectual property with a specific material are increasingly sought after. Such products frequently feature characters or designs associated with Disney, rendered in a durable, processed animal hide. This combination aims to offer both aesthetic appeal and practical functionality for carrying personal items.

The popularity of these goods stems from the enduring appeal of Disney characters and stories, coupled with the perceived value and longevity of the chosen material. Historically, similar products have been viewed as both fashionable accessories and potential collectible items, driven by consumer demand for merchandise that reflects personal interests and brand loyalty. This market benefits from the established reputation of the entertainment giant and the material’s association with quality.

The subsequent sections will address specific aspects related to the production, consumer considerations, care, and potential market value related to these types of products. This will include examining materials, manufacturing techniques, maintenance protocols, and factors impacting pricing and resale value.

Guidance on Acquisition and Upkeep

This section provides essential guidelines for selecting and maintaining items that combine Disney aesthetics with leather construction. Careful consideration and proper care extend the lifespan and preserve the value of these products.

Tip 1: Authenticity Verification: Prior to purchase, meticulously examine the item for official Disney licensing marks and hallmarks. Compare the design and construction against verified images from official sources to mitigate the risk of acquiring counterfeit goods.

Tip 2: Leather Quality Assessment: Evaluate the type and grade of the material employed. Full-grain leather generally represents the highest quality, followed by top-grain. Lower grades, such as bonded leather, offer reduced durability and aesthetic appeal.

Tip 3: Stitching and Hardware Inspection: Scrutinize the stitching for evenness, tightness, and the use of durable thread. Ensure all hardware components, such as zippers and buckles, function smoothly and are securely attached.

Tip 4: Proper Storage Techniques: When not in use, store the item in a cool, dry place away from direct sunlight and excessive humidity. Utilize a dust bag to prevent scratches and protect against dust accumulation.

Tip 5: Regular Cleaning Regimen: Implement a routine cleaning schedule using a leather-specific cleaner and conditioner. Follow the manufacturer’s instructions carefully to avoid damaging the material. Spot-test any cleaning product on an inconspicuous area before applying it to the entire surface.

Tip 6: Professional Restoration Considerations: For significant damage or staining, consider seeking professional leather restoration services. Attempting to repair such issues independently may result in further harm to the item.

Adhering to these guidelines ensures responsible acquisition and proper maintenance, maximizing the longevity and preserving the aesthetic appeal of items that combine Disney imagery with leather craftsmanship.

The subsequent section will explore the economic aspects of these specialized products, including pricing factors and potential resale value considerations.

1. Material quality

The selection of materials significantly influences the durability, aesthetics, and overall value of Disney-themed products utilizing leather. The quality of the hide impacts its resistance to wear and tear, its visual appeal, and its longevity, directly affecting the end product’s suitability for its intended purpose.

- Leather Grade

The grade of leather used in construction, such as full-grain, top-grain, or bonded, dictates its inherent strength and visual characteristics. Full-grain leather, derived from the outermost layer of the hide, exhibits superior durability and a natural grain pattern. Top-grain leather, sanded to remove imperfections, sacrifices some durability for a more uniform appearance. Bonded leather, composed of shredded leather scraps, represents the lowest grade and offers reduced longevity and aesthetic appeal. A backpack crafted from full-grain leather will withstand daily use more effectively than one constructed from bonded leather.

- Tanning Process

The tanning process employed to treat the hide influences its flexibility, water resistance, and colorfastness. Vegetable tanning utilizes natural tannins and produces a leather with a characteristic aroma and patina over time. Chrome tanning, a faster process, yields a more flexible and water-resistant leather. Improper tanning techniques can lead to leather that cracks, fades, or becomes brittle with age. A well-tanned leather will retain its color and pliability for an extended period.

- Finishing Techniques

Finishing techniques, such as dyeing, embossing, and coating, impact the leather’s surface appearance and protective properties. Dyeing imparts color to the leather, while embossing adds texture and decorative elements. Protective coatings enhance water resistance and prevent staining. Poorly applied finishes can crack, peel, or fade over time, detracting from the product’s aesthetic appeal. A properly finished leather surface will resist wear and maintain its visual integrity.

- Hardware Integration

The quality of hardware components, such as zippers, buckles, and clasps, complements the leather’s durability and functionality. Low-quality hardware can fail prematurely, compromising the item’s usability. Corrosion-resistant materials and robust construction are essential for ensuring long-term performance. A backpack with durable metal zippers and reinforced straps provides greater reliability than one with flimsy plastic components.

These facets of material quality are directly linked to the long-term satisfaction derived from owning a Disney-themed item. Selecting products constructed with high-grade leather, employing appropriate tanning and finishing techniques, and incorporating durable hardware ensures both aesthetic appeal and functional longevity. The initial investment in superior materials translates to extended use and sustained value over time. Conversely, prioritizing cost savings by opting for lower-quality materials often results in premature wear, reduced aesthetic appeal, and diminished overall value.

2. Licensing authenticity

Licensing authenticity is paramount when considering items that feature both Disney intellectual property and leather as a material. The legitimacy of the licensing agreement directly impacts the product’s value, quality, and legal standing in the marketplace.

- Legal Compliance

Official licensing ensures that the manufacturer has secured the necessary legal permissions to utilize Disney characters, logos, and imagery. This compliance safeguards both the consumer and Disney from copyright infringement and potential legal repercussions. Purchasing unlicensed merchandise supports illicit activities and undermines the value of authorized products. A product bearing a Disney character without the appropriate licensing marks is indicative of potential legal issues.

- Quality Control Standards

Licensed manufacturers are typically held to stringent quality control standards dictated by Disney. These standards encompass material selection, construction methods, and safety regulations. Adherence to these guidelines ensures that the product meets established benchmarks for durability, aesthetic appeal, and user safety. Unlicensed products often lack such quality control measures, resulting in inferior craftsmanship and potential safety hazards. A licensed item is more likely to withstand regular use without premature wear or defects.

- Brand Protection

Licensing protects the Disney brand image and reputation. Authorized products uphold the company’s established standards for creativity, artistry, and overall quality. Unlicensed merchandise frequently compromises brand integrity through inaccurate character depictions, substandard materials, and poor construction. This erosion of brand value can negatively impact consumer perception of Disney products as a whole. Authenticity helps to preserve the integrity and value of the Disney brand.

- Ethical Manufacturing Practices

Licensed manufacturers are more likely to adhere to ethical labor practices and environmentally responsible production methods. Disney often requires licensees to comply with fair labor standards and sustainable sourcing initiatives. Purchasing licensed products supports companies that prioritize ethical business practices. Unlicensed manufacturers may operate outside of established regulatory frameworks, potentially exploiting workers or engaging in environmentally damaging practices. Verification of licensing authenticity provides assurance of ethical manufacturing standards.

The intersection of licensing authenticity and material selection dictates the long-term value and appeal of specialized products. Authenticity guarantees compliance with legal, quality, and ethical standards, enhancing the consumer experience and protecting the interests of both the buyer and the intellectual property holder. Neglecting to verify licensing authenticity exposes consumers to legal risks, inferior products, and the potential support of unethical manufacturing practices.

3. Construction durability

Construction durability is a critical factor determining the longevity and functional performance of items utilizing leather, especially when combined with licensed intellectual property. The manner in which materials are assembled directly affects the product’s ability to withstand regular use and maintain its structural integrity over time.

- Seam Reinforcement

The method of seam construction significantly impacts the product’s resistance to stress and potential failure points. Reinforced seams, achieved through techniques such as double stitching or the use of binding tape, distribute stress more evenly and prevent seam separation under heavy loads. A product with poorly reinforced seams may exhibit premature wear and tear, particularly in areas subject to high stress. For example, a handle attachment point that is not adequately reinforced is likely to fail under the weight of a full load.

- Material Thickness and Density

The thickness and density of the leather employed in the construction directly correlate with its resistance to abrasion, punctures, and tearing. Thicker, denser materials offer greater protection against physical damage, extending the product’s lifespan. Conversely, thin or loosely woven materials are more susceptible to damage and may degrade rapidly with regular use. A thinly skinned leather is more prone to scrapes and scratches than a thicker one.

- Hardware Attachment Methods

The means by which hardware components, such as zippers, buckles, and straps, are attached to the leather body influence the overall structural integrity of the product. Secure attachment methods, such as rivets, reinforced stitching, or integrated mounting plates, prevent hardware components from detaching under stress. Poorly attached hardware is a common point of failure, rendering the product unusable. A strap secured with flimsy stitching may detach easily.

- Base and Corner Reinforcement

The base and corners of an item are often subjected to increased wear and tear due to contact with surfaces and the concentration of weight. Reinforcing these areas with additional layers of material or protective elements enhances their resistance to abrasion and prevents premature wear. Unreinforced bases and corners are prone to scuffing, tearing, and eventual structural failure. A product with reinforced corners will last longer than one that doesn’t reinforced corner.

These elements of construction durability collectively influence the long-term usability and aesthetic appeal of products. The selection of robust construction techniques and high-quality assembly methods ensures that these items can withstand the rigors of daily use while maintaining their structural integrity. By prioritizing durable construction, manufacturers enhance product longevity, minimize the risk of premature failure, and provide consumers with greater value and satisfaction. An item built with these principles in mind will offer superior performance and extended life.

4. Character depiction

The visual representation of Disney characters on leather goods directly influences consumer appeal and market value. Authentic and high-quality character depictions enhance the desirability and perceived value of these items. Inaccurate or poorly executed character designs can diminish consumer interest and negatively impact brand perception. The accuracy, detail, and artistic style of character portrayals are critical determinants of consumer satisfaction. Consider the contrast between a meticulously crafted image of Mickey Mouse on a leather accessory, which commands a premium price, versus a poorly rendered, generic imitation, which lacks market appeal. This is the essence of characterizing Disney characters on the leather product.

The implementation of character designs involves considerations of licensing agreements, artistic integrity, and manufacturing techniques. Authorized manufacturers adhere to specific guidelines provided by Disney to ensure accurate and consistent character representations. These guidelines dictate aspects such as color palettes, proportions, and stylistic conventions. Deviations from these standards can result in the rejection of the product or legal action. The use of durable printing or embossing methods is essential for maintaining the integrity of the character design over time. A faded or peeling character image diminishes the product’s aesthetic appeal and reduces its perceived value. Careful attention to detail is crucial for capturing the essence of each character, and bringing them to life.

The economic implications of character depiction are significant. Limited-edition or collectible items featuring iconic characters often command higher prices in the secondary market. The rarity and artistic merit of these items contribute to their collectibility and investment potential. Conversely, mass-produced items with generic character designs may face increased competition and lower profit margins. Understanding the nuances of character depiction is essential for both manufacturers and consumers. Manufacturers must prioritize accuracy, quality, and adherence to licensing guidelines to maximize the value of their products. Consumers should carefully examine character designs to ensure authenticity and assess their aesthetic appeal. These processes safeguard the value of both product and intellectual properties.

5. Care requirements

Proper maintenance protocols are essential for preserving the integrity and aesthetic appeal of leather products featuring Disney intellectual property. The specific care requirements vary depending on the type of leather used, the finishing techniques applied, and the environmental conditions to which the item is exposed. Neglecting proper care can lead to premature wear, discoloration, and structural damage, diminishing the item’s value and shortening its lifespan.

- Cleaning Protocols

Regular cleaning is necessary to remove surface dirt, dust, and stains. The appropriate cleaning method depends on the type of leather and the nature of the soiling. Gentle cleaning with a soft, damp cloth is suitable for routine maintenance. Stubborn stains may require specialized leather cleaners, but harsh chemicals and abrasive cleaners should be avoided to prevent damage. For example, the buildup of oils and dirt on handles can be mitigated by regular cleaning, preventing discoloration and cracking.

- Conditioning Practices

Leather conditioning replenishes natural oils lost over time, preventing the material from drying out and cracking. Leather conditioners should be applied periodically, following the manufacturer’s instructions. Over-conditioning can lead to excessive oil buildup, while under-conditioning can result in dryness and brittleness. Proper conditioning maintains the leather’s suppleness and prevents surface damage. Application of a high-quality conditioner every few months can significantly extend the life of such items.

- Protection Measures

Protecting leather from environmental factors, such as sunlight, humidity, and extreme temperatures, is crucial for preventing damage. Direct sunlight can cause fading and discoloration, while excessive humidity can promote mold growth. Storing items in a cool, dry place away from direct sunlight minimizes these risks. Applying a leather protectant can enhance resistance to water damage and staining. For example, storing it in a dust bag away from direct light can prevent fading and discoloration of the dye.

- Repair and Restoration

Promptly addressing minor damage, such as scratches and scuffs, can prevent further deterioration. Leather repair kits are available for minor repairs, but professional restoration services may be necessary for significant damage or discoloration. Delaying repairs can exacerbate the problem and lead to more extensive and costly restoration efforts. Timely repair of a small tear can prevent it from spreading and causing major structural damage.

These multifaceted care requirements collectively influence the long-term preservation and aesthetic appeal of Disney character items. By adhering to appropriate cleaning, conditioning, protection, and repair protocols, owners can maximize the lifespan, minimize the risk of damage, and sustain the value of these items. These care considerations ensures both the lasting value and continuing enjoyment for collectors. Proper maintenance of the leather complements the value of the intellectual property it displays.

6. Storage conditions

The preservation of items crafted from leather materials featuring Disney intellectual property is significantly influenced by the environment in which they are stored. Proper storage conditions mitigate the risk of damage and degradation, ensuring the longevity and maintaining the aesthetic appeal of these specialized products. The following considerations outline key aspects of effective storage practices.

- Humidity Control

Excessive humidity promotes the growth of mold and mildew, which can damage the leather fibers and cause discoloration. Conversely, extremely low humidity can lead to drying and cracking. Storing these items in a climate-controlled environment with a relative humidity level between 40% and 50% is recommended. A damp environment can cause the leather to become stiff and brittle or show signs of mildew on the surfaces.

- Temperature Regulation

Extreme temperature fluctuations can cause the leather to expand and contract, leading to structural damage and cracking. Maintaining a stable temperature, ideally between 65F and 75F (18C and 24C), minimizes these risks. Avoid storing these items in attics, basements, or other locations subject to significant temperature variations. Over time, the leather may show signs of wear and tear from extreme temperature changes.

- Protection from Light Exposure

Prolonged exposure to direct sunlight can cause fading and discoloration of both the leather and any character designs or embellishments. Store items in a dark or dimly lit location, or utilize protective covers to shield them from ultraviolet radiation. Direct sunlight breaks down materials and causes damage from UV exposure.

- Physical Protection

Protecting items from physical damage, such as scratches, abrasions, and crushing, is essential for maintaining their structural integrity. Store these items in dust bags or protective cases to prevent surface damage. Avoid stacking heavy objects on top of them, as this can cause deformation or permanent creasing. Proper storage, utilizing shelves or hanging, protects these specialized items.

These storage considerations collectively contribute to the long-term preservation of items featuring both Disney themes and leather. By controlling humidity, regulating temperature, protecting from light exposure, and providing physical protection, owners can significantly extend the lifespan, minimize the risk of damage, and sustain the value of their items. Failure to adhere to these storage guidelines can result in irreversible damage and diminished aesthetic appeal. The storage methods and conditions play a critical role.

7. Resale potential

The subsequent market value of these items integrates factors related to initial quality, brand recognition, and scarcity. Consumer interest and collector demand influence the capacity to recoup the initial investment or generate profit upon resale. Understanding factors contributing to resale potential informs purchasing decisions and long-term ownership strategies.

- Limited Edition Status

Items produced in limited quantities or as part of exclusive collections frequently command higher resale values. Scarcity drives collector demand, creating a competitive market for acquiring these items. The presence of a certificate of authenticity or verifiable proof of limited edition status further enhances the resale potential. A limited-edition design featuring a popular character and a serialized number ensures authenticity and value.

- Character Popularity and Rarity

The popularity of the depicted Disney character and the rarity of the specific design contribute to the resale value. Characters experiencing a resurgence in popularity or designs commemorating significant milestones within the Disney universe often attract increased collector interest. Items featuring lesser-known or retired characters may also command higher prices due to their scarcity. An item depicting a classic character that is no longer prominently featured in Disney media may generate higher resale value.

- Condition and Maintenance Records

The condition of the item significantly impacts its resale value. Items maintained in pristine condition, free from scratches, stains, or other forms of damage, command higher prices. Maintaining detailed records of cleaning, conditioning, and repair services demonstrates responsible ownership and enhances buyer confidence. Proper storage conditions, such as climate control and protection from sunlight, also contribute to preserving the item’s condition. An item that has had the best care can increase its resell value for a long time.

- Original Packaging and Documentation

Retaining the original packaging, tags, and documentation, such as purchase receipts or certificates of authenticity, enhances the perceived value and credibility of the item. Original packaging provides additional protection during shipping and storage, minimizing the risk of damage. Documentation verifies the item’s authenticity and provenance, reassuring potential buyers. An item sold with all of its original components and paperwork can get a higher purchase price.

These aspects directly influence the market value of products combining leather and Disney intellectual property. Collectors base prices in part on these components. Consideration of these factors informs acquisition and maintenance strategies, facilitating informed decision-making in the secondary market.

Frequently Asked Questions Regarding Disney-Themed Products Utilizing Leather

This section addresses common inquiries and misconceptions regarding the acquisition, care, and valuation of items combining Disney intellectual property and leather as a primary material.

Question 1: How can one verify the authenticity of a Disney-themed product using leather?

Authentication requires close examination for official Disney licensing marks, holograms, and unique serial numbers. Cross-reference the product’s design and features with images from official Disney merchandise catalogs or websites. Purchase from authorized retailers to minimize the risk of acquiring counterfeit goods.

Question 2: What types of leather are commonly used in the manufacture of Disney-themed products?

Full-grain, top-grain, and bonded leather are employed in varying degrees. Full-grain represents the highest quality, exhibiting durability and natural grain patterns. Top-grain leather offers a more uniform appearance but reduced durability. Bonded leather, composed of shredded scraps, offers lower durability and is therefore the least desirable.

Question 3: What are the recommended cleaning procedures for such products?

Gentle cleaning with a soft, damp cloth is suitable for routine maintenance. Specialized leather cleaners, specifically formulated for the type of leather in question, may be used for more stubborn stains. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the surface.

Question 4: What steps can be taken to prevent the leather from drying out and cracking?

Regular application of leather conditioner replenishes natural oils lost over time, preventing dryness and cracking. The frequency of conditioning depends on the type of leather and the environmental conditions, but generally, application every few months is recommended.

Question 5: How should Disney-themed items crafted from leather be stored to prevent damage?

Storage in a cool, dry place away from direct sunlight is essential. Protection from excessive humidity and extreme temperature fluctuations is also crucial. Utilizing dust bags or protective cases minimizes the risk of scratches and abrasions.

Question 6: What factors contribute to the resale value of these items?

Resale value is influenced by factors such as limited edition status, character popularity, condition, and the presence of original packaging and documentation. Items maintained in pristine condition, featuring popular characters, and accompanied by certificates of authenticity command higher prices in the secondary market.

This FAQ section provides clarification on key aspects of acquiring and maintaining items featuring Disney and crafted from leather. Adhering to these guidelines will help extend their longevity and preserve their value.

The concluding section will offer a summary of key considerations and provide a final perspective on this specialized product category.

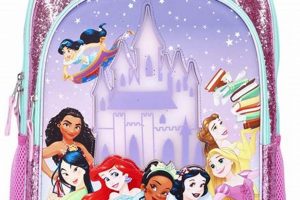

Concluding Thoughts on Disney Backpack Leather

This article has explored key aspects related to goods incorporating Disney intellectual property and leather as a material, addressing acquisition, maintenance, and economic considerations. Verification of authenticity, material assessment, appropriate cleaning and storage, and awareness of factors influencing resale value are vital for informed consumer decisions. Quality and long-term value hinge on these criteria.

The intersection of Disney’s enduring appeal and leather’s perceived value presents both opportunities and challenges. Informed selection, diligent care, and realistic expectations are crucial for ensuring satisfaction and preserving the investment in such items. Careful deliberation and responsible stewardship are recommended for those engaging with this specialized product category.